High Quality OEM Resistant Castings Of Refuse Incinerator Companies - Cast steel grate bars, wear parts of waste to energy furnace – Xingtejia

High Quality OEM Resistant Castings Of Refuse Incinerator Companies - Cast steel grate bars, wear parts of waste to energy furnace – Xingtejia Detail:

1. Casting process: Shell mold precision casting

2. Steel grade: GX130CrSi29(1.4777) ( Also can be as your requirement)

3. Dimensional Tolerance of cast: DIN EN ISO 8062-3 grade DCTG8

4. Geometrical Tolerance of cast: DIN EN ISO 8062 – grade GCTG 5

5. Application: Waste to energy incineration plants.

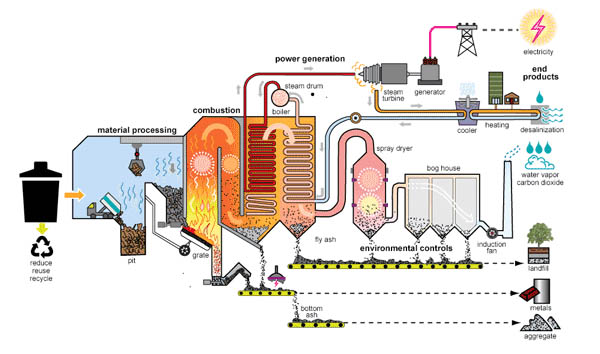

Garbage disposal is now a very serious global problem. Trash to energy is the currently most reasonable treatment. In recent years, many countries with strong economic strength have begun to pay attention to this point. A lot of money has been invested in the construction of waste incineration power plants. This has not only brought great improvement to our environment. At the same time, it has brought us great economic benefits.

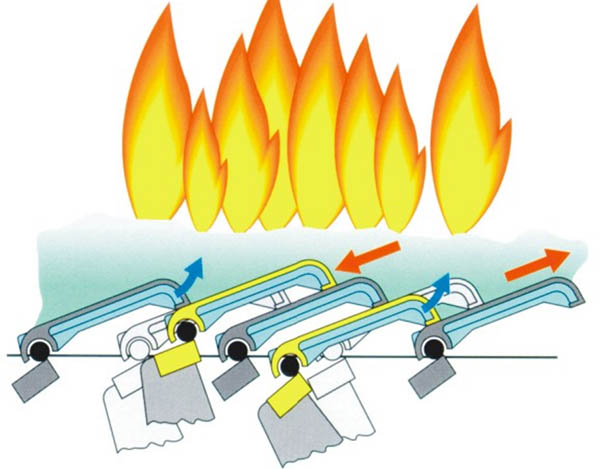

As shown in the figure, grate bars play an important role in waste incineration. In high temperature and very harsh environment, Low quality grate will greatly affect the efficiency of waste incineration, and its service life is very short. You need to replace it very often.

However, with over 10 years casting experience, we can solve the problems for you.

Steel Grade we usually use. (It can also be as your requirements.)

Chemical composition % of steel GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 – 1.4 |

1 – 2.5 |

0.5 – 1 |

max 1 |

max 0.035 |

max 0.03 |

27 – 30 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 1.5 |

3 – 6 |

max 0.04 |

max 0.03 |

25 – 28 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 2 |

19 – 22 |

max 0.04 |

max 0.03 |

24 – 27 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 2 |

11 – 14 |

max 0.04 |

max 0.03 |

24 – 27 |

max 0.5 |

| Mechanical properties(ASTM A297 Grade HH)1.4837 | UTS: Min 75 Ksi/515 Mpa |

| YS: Min 35 Ksi/ 240 Mpa | |

| Elongation: in 2 in: Min 10 % | |

| Hardness: Min 200 BHN (3 places on speciment)” | |

| Microstructure/Metallography | Predominantly Austenitic structure containing dispersed carbides |

| SoundnessTest/X-ray or UT | RT per ASTM E446 Level II |

| UT per ASTM A609 Level II | |

| NDT/LPI or MPI | MPI as per ASTM E709/E125 LEVEL II |

| LPI as per ASTM E165 Level II” | |

| Final Visual Inspection | ASTM A802 Level II |

| Package | Iron case or Wooden case. |

Our Main Market Are

OEMs and engineering companies

Waste to Energy plants

Operating companies

Biomass units

Coal-fired power plants

Service companies for maintenance operations

Different kinds of OEM grate bars

Well finished grate bars

Mature Process And Strict Quality Control Is Why will you choose us

For more inquiries or technical questions, please contact XTJ Service Team. We will provide the most reasonable technical solution and the best quotation according to your product.

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products and solutions into the market each year for High Quality OEM Resistant Castings Of Refuse Incinerator Companies - Cast steel grate bars, wear parts of waste to energy furnace – Xingtejia , The product will supply to all over the world, such as: Porto, Estonia, Croatia, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,