High Quality OEM Stirred Ball Mill Exporters - Grate bar and Side wall, Wear Parts on pallet cars and sinter/pellet cars – Xingtejia

High Quality OEM Stirred Ball Mill Exporters - Grate bar and Side wall, Wear Parts on pallet cars and sinter/pellet cars – Xingtejia Detail:

1. Casting process: Shell mold precision casting

2. Steel grade: 1.4777 1.4823 1.4837 1.4848

3. Dimensional Tolerance of cast: DIN EN ISO 8062-3 grade DCTG8

4. Geometrical Tolerance of cast: DIN EN ISO 8062 – grade GCTG 5

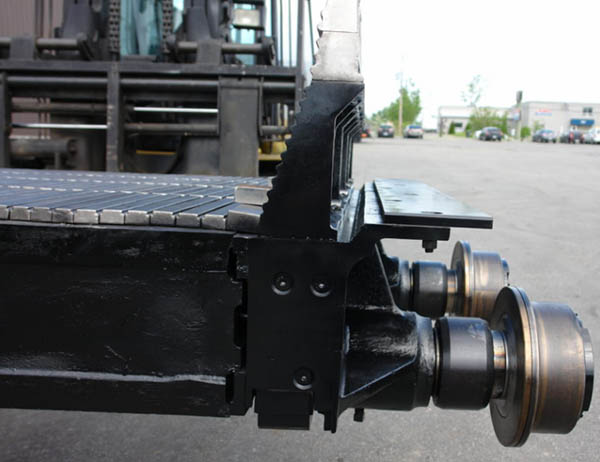

5. Application: Wear Parts on pallet cars and sinter cars.

We are the leading supplier to pallet cars and sinter cars manufacturers and the large steel mills. With over 10 years’ casting experience, these resistant parts produced by us always have good mechanical property and perfect cast surface. Mature technology has well controlled our production cost, so that you can order low-cost products from us. In recent years, the increase of production capacity has also guaranteed your delivery date.

Steel Grade we usually use. It can also be as your requirements.

Chemical composition % of steel GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 – 1.4 |

1 – 2.5 |

0.5 – 1 |

max 1 |

max 0.035 |

max 0.03 |

27 – 30 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 1.5 |

3 – 6 |

max 0.04 |

max 0.03 |

25 – 28 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 2 |

19 – 22 |

max 0.04 |

max 0.03 |

24 – 27 |

max 0.5 |

Chemical composition % of steel GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 – 0.5 |

1 – 2.5 |

max 2 |

11 – 14 |

max 0.04 |

max 0.03 |

24 – 27 |

max 0.5 |

| Mechanical properties(ASTM A297 Grade HH)1.4837 | UTS: Min 75 Ksi/515 Mpa |

| YS: Min 35 Ksi/ 240 Mpa | |

| Elongation: in 2 in: Min 10 % | |

| Hardness: Min 200 BHN (3 places on speciment)” | |

| Microstructure/Metallography | Predominantly Austenitic structure containing dispersed carbides |

| SoundnessTest/X-ray or UT | RT per ASTM E446 Level II |

| UT per ASTM A609 Level II | |

| NDT/LPI or MPI | MPI as per ASTM E709/E125 LEVEL II |

| LPI as per ASTM E165 Level II” | |

| Final Visual Inspection | ASTM A802 Level II |

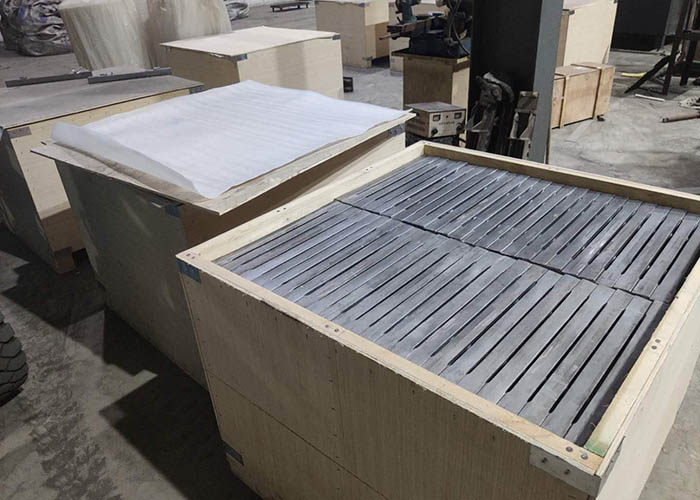

| Package | Iron case or Wooden case. |

In current competitive economy, maintaining quality while reducing costs can be challenge for every business.

But cooperating with xtj, you don’t have to think about it. We are a professional factory, direct supply after production. And there are professional technical personnel and after-sales team to provide you with technical services. In this way, you can get the best service while minimizing the cost.

For more inquiries or technical questions, please contact XTJ Service Team. We will provide the most reasonable technical solution and the best quotation according to your product.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for High Quality OEM Stirred Ball Mill Exporters - Grate bar and Side wall, Wear Parts on pallet cars and sinter/pellet cars – Xingtejia , The product will supply to all over the world, such as: Pakistan, Suriname, Suriname, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our experienced advice and service can lead to more suitable choice for the customers.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.