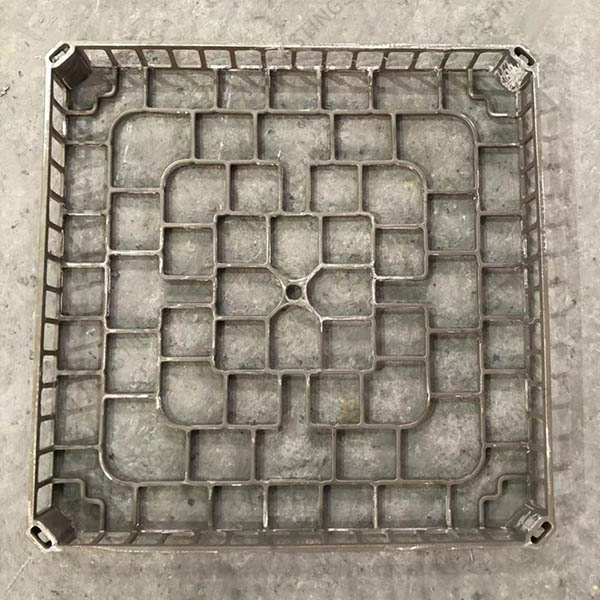

High Quality OEM Vacuum Furnace Plate Companies - Heat Treatment trays/baskets, Annealing Furnace Tray – Xingtejia

High Quality OEM Vacuum Furnace Plate Companies - Heat Treatment trays/baskets, Annealing Furnace Tray – Xingtejia Detail:

1. Cast process: Investment casting

2. Steel Grade: As your requirement

3. Dimensional Tolerance of cast: DIN EN ISO 8062-3 grade DCTG8

4. Geometrical Tolerance of cast: DIN EN ISO 8062 – grade GCTG 5

XTJ provides the right solution corresponding to your needs, it includes:

1. Standard products for the most common types of furnaces worldwide like Base Trays, Intermediate Grids, Baskets etc.,

2. Customized solution designed to the customer’s requirements.

Customized fixtures are designed to:

1. Maximize loading of customer’s components

2. Minimize fixture’s weight

3. Minimize the distortion of components

4. Provide a stable fixture

5. Prevent shock damage of component during loading and handling

6. Maximize service life of fixture

Investment castings are also referred to as precision castings, lost wax castings

The term investment casting is derived from the process of investing a pattern with refractory materials.

In the investment casting process, wax pattern is the first step, multiple wax pattern can be assembled into one large pattern to be cast in one batch pour, and then coated with a refractory ceramic material. The wax is melted out and molten metal is poured into the cavity where the wax pattern was. The metal solidifies within the ceramic mold and then the metal casting is broken out.

Due to the properties of wax, investment castings are normally small, our maximum investment casting weight can be reach to 88 lbs.

Because of the complex process and high cost of pattern die, normally investment castings are expensive, but for mass production of small parts, the average cost of investment castings are sometimes lower than that of no-bake sand castings, and the benefits of investment castings are very demonstrable. The advantages of investment castings are:

● Excellent surface finish

● High dimensional accuracy

● No flash or parting lines

● Extremely intricate parts are castable

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for High Quality OEM Vacuum Furnace Plate Companies - Heat Treatment trays/baskets, Annealing Furnace Tray – Xingtejia , The product will supply to all over the world, such as: Plymouth, Afghanistan, Nigeria, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.